I recently had the pleasure of visiting the TAFE Queensland Acacia Ridge campus, an outstanding example of Vocational Education and Training (VET). It’s a dynamic hub for quality VET, home to passionate teachers and highly engaged students.

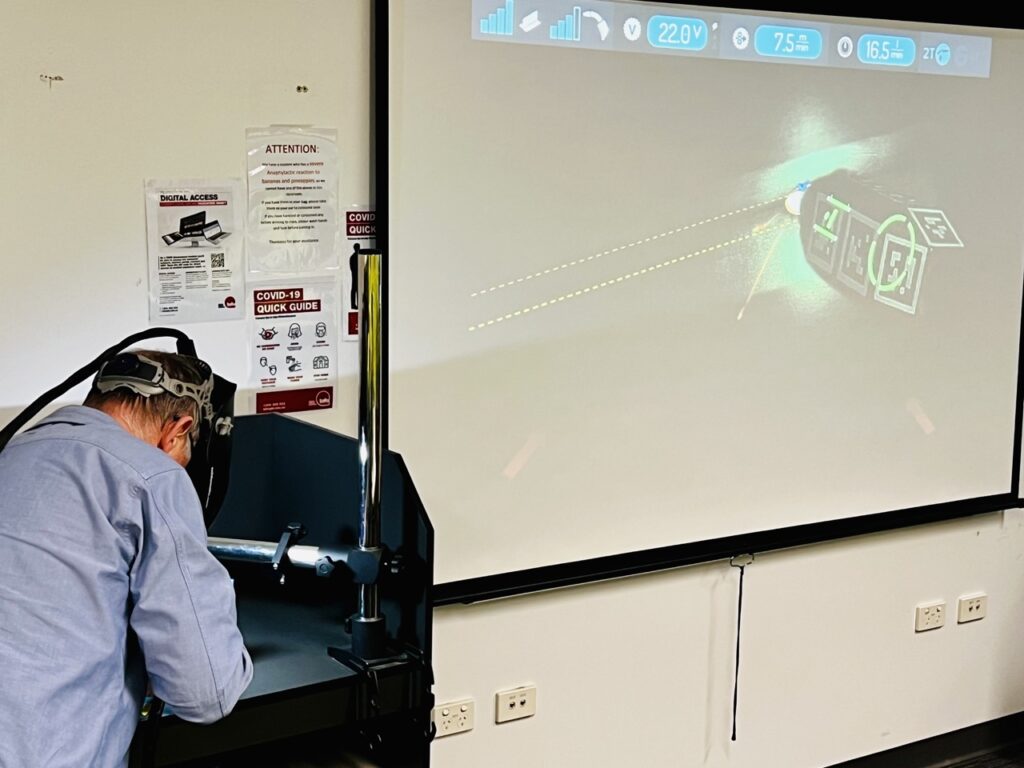

One of the highlights (with more to be shared soon) was the state-of-the-art augmented reality (AR) welding simulator. This training solution is highly innovative and offers one of the most realistic welding experiences aside from the real thing.

Over the past few years, I’ve encountered a lot of AR teaching tools. While many have been a bit ‘gimmicky,’ (some being quickly discarded by Registered Training Organisations (RTOs) for being ineffective or unrealistic), this technology really stood apart.

Kevin, a passionate trainer, gave us a demo, letting our group of learners give it a try too. He explained how this particular technology has significantly impacted the quality of welding training.

As an educator, I frequently ponder what it takes for someone to become competent in a task or occupation. Welding is particularly challenging to learn. It’s a skill that demands extensive practice and a nuanced understanding of the trade. The journey to becoming an experienced welder is long, often taking place in a noisy and risky environment. If you’ve ever tried welding, you’ll know that the goggles make it effectively pitch black, adding to the challenge of teaching the skills safely and effectively.

Other considerations include:

- The amount of metal wasted as students learn and refine their skills.

- The inherent risks involved, including electrical, fire, airborne hazards, and potential damage to vision.

These factors alone, I think, justify the cost of AR in welding training. Yet this technology offers more to learners in the way of providing immediate feedback on aspects like angle, travel speed, and aim. It enables students to practice safely in a low-stakes environment, receiving instant feedback on their technique.

Various visuals within the training system guide students as they weld, which enhances learning. One particular insight from Kevin that resonated with me was the comparison between traditional welding training and this contemporary approach. In the past, significant waste and expense were inevitable as students required extensive practice time.

Kevin highlighted how the AR system has allowed students to hone their skills to a point where, once they engage with a real welder, they can perform a quality weld quickly, safely, and effectively. This not only reduces waste but also dramatically shortens the training time.

A huge thanks goes to my colleagues Helen Bulle and Dr. Imante Markeviciute from Griffith University for arranging this visit and allowing me the opportunity to explore many examples first class TVET practice in Australia.

Case Studies

Accellier Success Stories

Celebrating the success of the E-Learning Facilitator Micro-credential (TAEDEL501)

Learn more about our TAEDEL501 Facilitate E-Learning Micro-credential.

Accellier Graduate Story: Marion

Marion, a successful Accellier Certificate IV in Training and Assessment graduate tells her story.

Qualified visual arts trainer videoAccellier and the NSW Department of Planning, Industry and Environment

Accellier was approached to assist over 50 highly skilled professionals within the organisation achieve Certificate IV in Training and Assessment.

Department of Planning, Industry and Environment